At Toyota Workers Are Accountable for Which of the Following

I personally was in the field for at least 180 working days during that time and even spent one week at a non-Toyota plant doing assembly work and spent another five months as part of a Toyota team that was trying to teach TPS at a first-tier supplier in Kentucky. A joint effort between management and workers tried to address the following issues.

Lean Management Works For Everyone Management For Everyone It Works

Project Sponsor 4 The Toyota Production System emphasizes the importance of making problems visible by doing of all of the following EXCEPT.

. In the meantime you can call 877 249-0086 to speak with a Toyota Insurance Management Solutions agent about current UBI options. Eliminating waste is just one-third of the equation for making lean successful. While Toyota Auto Insurance does not currently offer a usage-based insurance option we are hard at work to bring one to our customers in the future.

Toyota delegates to workers diverse responsibilities and real authority. The Toyota Motor Corporation is responsible for some of the best-selling car models such as the Corolla or Camry. It underscores the place of its customers in all its operations and that all its efforts target to leave them satisfied and marvelled by its products.

Build an inclusive future. Yoshihide Tachino the attorney for the victim and his family said Toyota was responsible for mismanagement for allowing the harassment to continue. Making workers responsible for producing high quality.

According to our recent CEO Benchmarking Report holding people accountable is difficulteven for leaders who head up companies. When a worker suffers psychologically from the traumatic experience of harassment that worker may continue to suffer even after he or she is able to return to work Tachino said in a. Under the traditional approach the optimal order quantity is _____ where under the kanban approach the optimal order quantity is _____.

Toyota worker questions work self-isolation following COVID scare Back to video We have been told from the beginning if exposed the best thing to do is be in a room and now people are at work. Toyota only hires workers with a six sigma green belt. Eighteen percent of the CEOs we surveyed cited holding people accountable as their biggest weakness.

Maintaining their own equipment Keeping the surrounding work area clean Help each other when difficulties arise Continually improving product quality Continually improving the production process. All of the above. Fortunately one of the most outstanding features of Toyota is its ability to adapt and improve.

2 and 3 only. Toyota Industries and its employees pledge to respect the privacy of individuals and refrain from discrimination based on race religion gender nationality disability or any other factor not directly related to an individuals work performance. 3 The person or group accountable for ensuring that the project has clear direction and support is the.

During the fiscal year ended March 2021 Toyota generated sales and revenue. Toyota views its workers as an integral part of the value-added system. Freedom to move for everyone.

Its key to achieving business results and yet many business leaders fail to hold employees accountable. At Toyota workers are accountable for which of the following. Toyota invests time and money in worker training.

Designing in quality insisting on quality materials and making workers responsible for quality. 1 2 and 3. Eliminating overburden to people equipment and eliminating unevenness in the production schedule is just as important yet generally not understood at companies attempting to implement lean principles.

Toyota mission statement is To attract and attain customers with high-valued products and services and the most satisfying ownership experience in AmericaThis statement reveals what the company holds dear in all its operations. 1 and 2 only. In 1992 Toyota started a humanization of the production system and of work in its Kyushu plant.

100 percent inspection of raw materials work-in-process and finished goods. In news regarding automaker Toyotas continuing problems with unintended acceleration a sudden increase in speed that may be linked to several accidents and deaths since 2001 preliminary findings from federal officials seem to support the companys claims that problems lie not in faulty electronics but rather in other issues such as sticking pedals. 1 and 3 only.

Toyota Industries will not tolerate sexual harassment in the workplace due. But as Toyota management added more and more responsibilities to his work load Uchino began to feel the strain of the enormous overtime that was expected - and mostly unpaid. No one person can be responsible for the design of a whole system.

Toyota Motor Corporation uses various mission statements for its businesses in different markets. 1 on a question. Colored markers or cards are used in kanban production control systems to.

Toyotas corporate mission statement has the following key elements that reflect the enterprise and the purpose and goals of its business. Following his father and grandfather who were both lifetime Toyota employees Uchino had joined the company right out of high school and was a good worker. Work like a tortoise not the hare.

Using View the full answer.

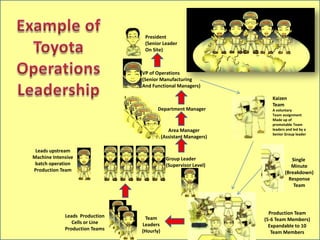

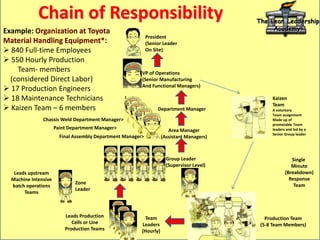

Toyota Operational Leadership Structure

Toyota Philosophy Vision Philosophy Company Toyota Motor Corporation Official Global Website Philosophy Toyota Company

Toyota Production System Staff Motivation Management Skills Business Leadership

Organizational Structure Of Toyota Motors 2 Organizational Structure Toyota Motors Toyota Company

Collision Of Pju Light Pole In Duren Sawit Toyota Rush Driver Examined By East Jakarta Traffic

This Hero Is Taking Over Jq215 Vlog Today Batman Reveals Himself Or Is It Someone Else Youtube Vlogging Hero Youtube

Pdf Learning To Lead At Toyota

Toyota Production System 14 Solid Principles Lean Six Sigma Business Process Management Principles

The 5s Method Poster Leadership Management Leadership Development Activities Change Management

Improving Lives And Sharing Benefits With Patient Centered Care Health Care Preventive Medicine Urgent Care

Implementation Guidelines For Sub Principles Of The Toyota Way Download Table

Toyota Operational Leadership Structure

Money Advice Chart Infographic Mortgage Tips

Larry Kim On Twitter Kaizen Business Process Management Kaizen Principle

Toyota Production System Toyota System Business

Each A Y Mcdonald Worker Is Proud To Stamp The Box W His Or Her Employee Code So Everyone Is Held Accountable For The Product Coding Mcdonald Be The Boss

Larry Kim On Twitter Kaizen Business Process Management Kaizen Principle

Comments

Post a Comment